Overview

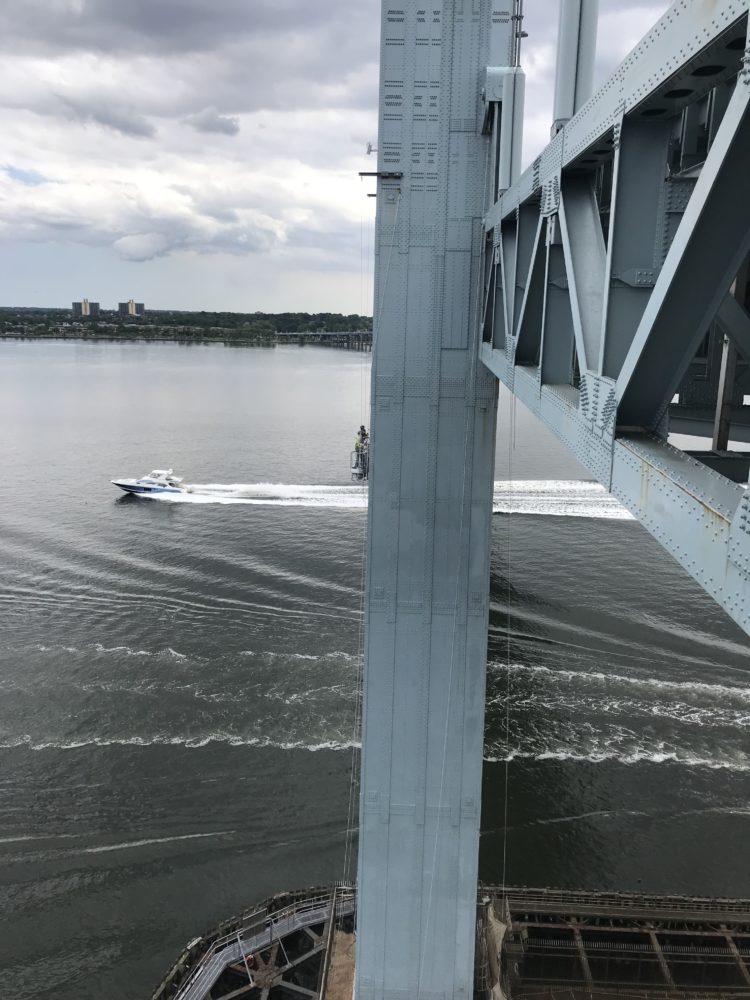

LiRo provided construction inspection services for the rehabilitation of the bridge anchorages to provide both protection and humidity control around the cable splays. In addition, the electrical systems within the anchorage have been upgraded with the replacement of all lighting fixtures with energy efficient LED units; and the installation of additional control access and digital video elements. The project also included the maintenance of coatings on the main and suspender cables, as well as the lower half of the main towers. The implementation of open road tolling and removal of the existing toll barrier was added to the project scope by an amendment.

About the Project

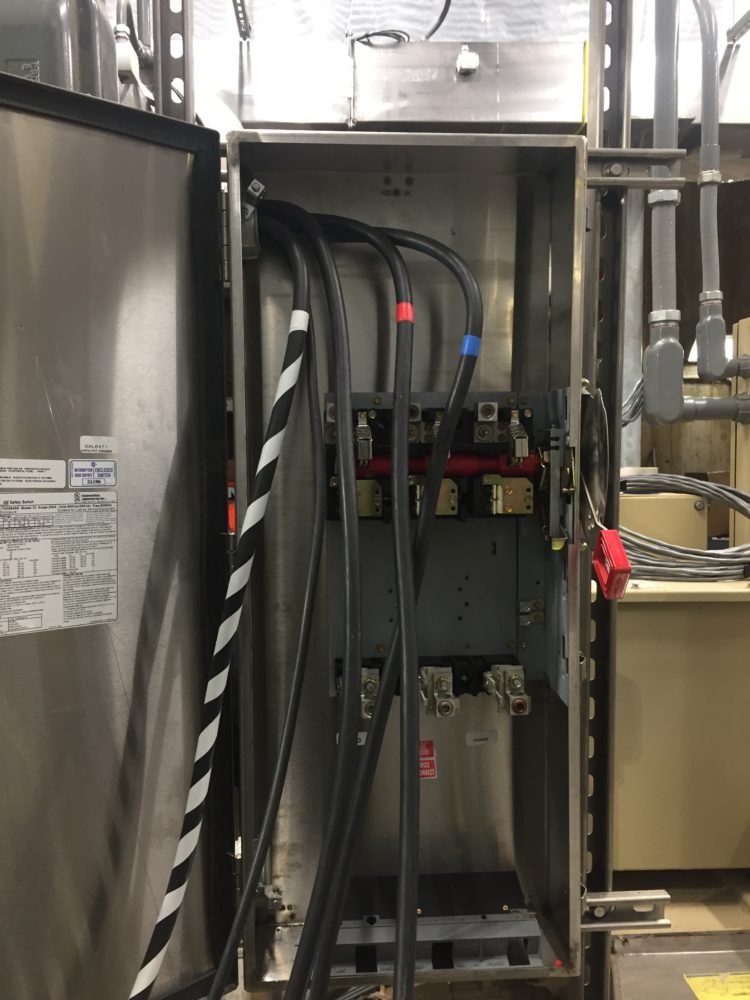

The work in the anchorages was focused on the construction of steel enclosures around the splay cables and the installation of dehumidification equipment. The installation of new inspection stairs and landings was included within the new splay enclosures. To address water infiltration into the anchorages the scope of the project included the replacement of the existing anchorage roadway level sidewalk areas including the replacement of all access hatches and the construction of a new interior stair tower and shed. The electrical, fire, and security systems were upgraded with the replacement of all existing light fixtures with cost saving LED fixtures; added additional fixtures within the new splay cable enclosures; and installed additional fire and access control and digital video monitoring security components within the anchorage. The implementation of open road tolling at the bridge involved the use of expedited processes for the reconstruction of the bridge toll plaza that included superelevating the roadway for higher design speeds; the fabrication and installation of toll equipment gantry’s and separate toll equipment building and a toll equipment server room within the existing toll facility building. The new roadway grade and alignment required the installation of a new drainage system, construction of new slip-formed concrete barriers, the relocation of roadway lighting and placement of granular fills, and the construction of new asphalt pavement roadway surfaces. The work was performed over five stages and completed in seven months. The final stage included the expedited demolition of the existing toll barrier and final re-alignment of the roadway that provided three lanes of traffic with acceleration and deceleration lanes at the north end of the project.

Project Challenges & Solutions

Maintenance of bridge traffic during construction was accomplished by use of daily lane closures and the establishment of protected work zones at each anchorage by shifting lanes and installing temporary concrete barriers along each anchorage sidewalk area. This project required the close coordination with the design team and contractor to assure that all aspects of the work were completed on a very tight and demanding schedule. For the open road tolling phase, the contractor’s expedited schedule included work 24 hours per day, 7 days a week.